Optimaalinen hiukkaskoonteiden jakautuminen on välttämätöntä monilla valmistusalueilla, mukaan lukien lääke- ja kemian, pinnoitteet ja muut. Tämän hionnan prosessin todelliset perustana ovat olleet teollisuushyllyt, jotka ovat mahdollistaneet materiaalien ominaisuuksien tarkan hallinnan ja lopputuotteen tasalaatuisuuden takaamisen. Tarjoamme edistyneitä ja kunnollisia hiontaratkaisuja vastaamaan nykyaikaisten tuotantoympäristöjen vaativuutta.

1. Tarkkuus hiukkaskoon hallinnassa

Teollisuuden hyllyt käyttävät mekaanisia toimintoja, kuten iskua, leikkausta ja puristusta, jotta raaka-aineet saadaan pilkottua tasaisen kokoisiksi partikkeleiksi. Tällä kontrollilla yksittäisiin kiderakenteisiin asti valmistaja voi mukauttaa partikkelijakaumat sovelluksen tarpeisiin, olipa kyseessä aktiivisten yhdisteiden pinta-alan maksimointi tai varmistettu sileä tekstiuri kuluttajatuotteissa. Edistyneimmät muodot sisältävät reaaliaikaiset valvontajärjestelmät, jotka säätävät hyllyn parametreja automaattisesti tavoitejakaumien mukaisesti pitkäaikaisessa käytössä.

2. Vaikutus tuotteen suorituskykyyn

Hiukkasten tasainen jakauma vaikuttaa suoraan tuotteen keskeisiin ominaisuuksiin

• Parantunut liukoisuus ja bio saatavuus lääketehtailussa

• Parempi väjyvyys ja kiiltävyys maalauksissa ja pinnoitteissa

• Parannettu reaktiojärjestelmien tehokkuus kemiallisessa valmistuksessa

3. Säätömahdollisuus erilaisiin materiaaleihin

Moderni murskautusteknologia toimii kaiken välillä kalskaantuvien keraamisten ja elastisten polymeerien välillä hyödyntämällä tiettyjä suunnitteluja:

•Iskusystemit hauraalle materiaalille

•Kulutusjauhatus hyvin hienoksi

•Kuitumateriaalien murskaimet

Tämä monikäyttöisyys takaa parhaan käsittelyn riippumatta materiaalin ominaisuuksista tai tuotannon määrävaatimuksista.

4. Prosessin tehokkuus ja toistettavuus

Automaattiset ohjausjärjestelmät takaavat ehdollistetut käyttöolosuhteet, jotka antavat toistettavissa olevan erän. Suunnittelut ovat energiatehokkaita ja tarjoavat nopeamman toimintojen suorittamisen perinteisiin suunnitteluun verrattuna. Jäähdytysyksikkö on osa integroitua jäähdytysjärjestelmää välttääkseen lämmönsiirron vaurioita laajennetussa murskautusprosessissa.

5. Laadunvarmistuksen integrointi

Monimutkaisimmat hienonnikat varustetaan myös näytteenottajärjestelmillä, jotka mahdollistavat partikkelikoon määrittämisen prosessin aikana pysäyttämättä tuotantoprosessia. Tämä online-laatuohjaus mahdollistaa reaaliaikaisten parametrien säätämisen, jolloin varmistetaan vain spesifikaatioiden mukaisten tuotteiden tuotanto ja minimitään poikkeavien materiaalien ja materiaalihukkien syntymistä.

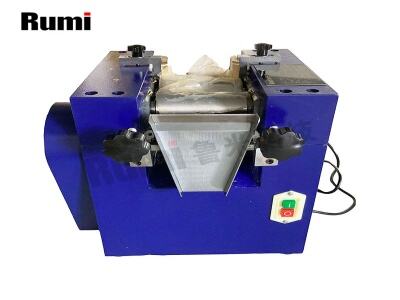

Rumin tuotevalikoimassa yhdistyvät teknologiset edistysaskeleet ja kestävä rakenne, joka takaavat pitkäaikaisen käytön. Konemme tukevat valmistajia tuottamaan korkealaatuisia tuotteita maksimaalisella tuotantotehokkuudella ja alhaisemmalla käyttökustannuksilla.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

BE

BE

IS

IS

AZ

AZ

BN

BN

EO

EO

LA

LA

MN

MN