For example, paint bead mill are nonconformist tool for factory workers to do paintings of the lot. These containers are extremely beneficial in which it prevents paint from being wasted and assists people to complete their work as fast and efficient as possible. Paint tanks are beneficial in the factories and an essential aspect of the painting process, we will discover in this text.

Over the years, one important change that factories have made with respect to their paint shops is learning how we can improve on the process of painting vehicles here at our facilities and this just simply comes with all things being equal, whether its drying or buffering.

Paint tanks are an essential equipment used widely in factories. Paint tanks are used in various applications, including car factories, furniture factories and toy factories. Those fishy tanks are built to hold paint, and mix it, so this is the same stuff you see in such things as cars, tables and toys. Paint tanks help keep the paint in one place so that it is accessible for workers when needed.

Perhaps the largest benefit of paint horizontal sand mill is they allow factories to conserve their paint. Paint, after all, is pretty precious stuff and no factory is going to waste it. If you put paint in the paint tank, it stays organized and is easy to access. This allows workers to at-a-glance access the paint they need without spilling any. Consequently, it wastes less paint and takes less time to do the work. This not only beneficial for the factories to reduce its costs but at the same time, it enables the workers to be more sensible by being punctual in their jobs.

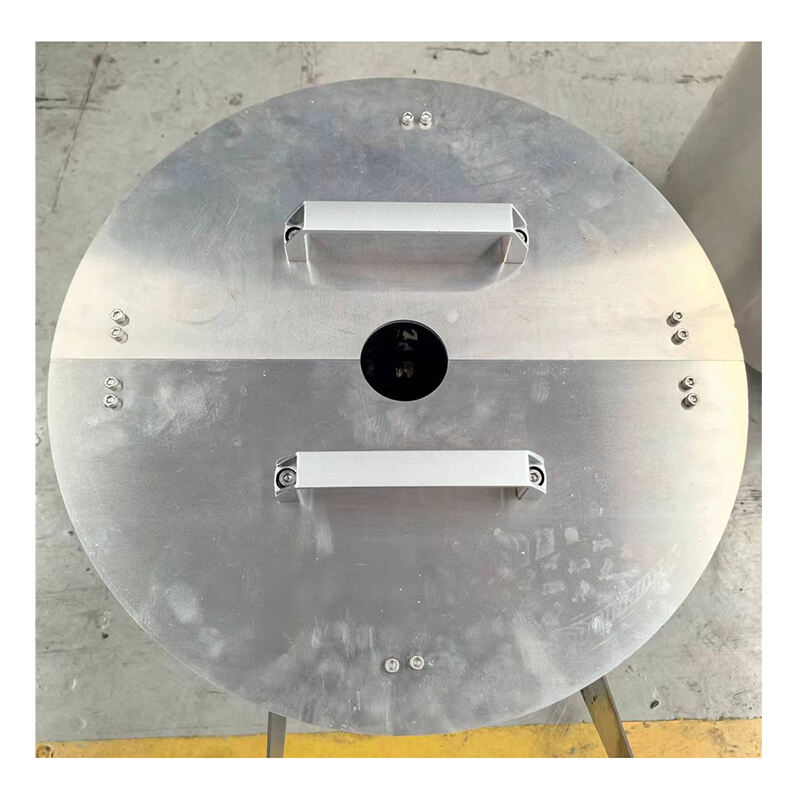

There are different types of paint tanks and they serve many kinds of jobs. Some paint tanks are small and they made them for quick use on little projects. Mini tanks are a great option for jobs that don’t require much paint. But on the opposite side, some huge paint tanks are made to store massive amounts of paint when big jobs need it. These enormous tanks are ideal for factories that require to paint many parts simultaneously. Then there are paint tanks that accommodate certain kinds of paint better than others. Other paints are thicker, which requires more of a tank to mix and store.

The cleanliness and maintenance of paint tanks are excessively important. Same with the paint, if you let it dry in your tank – Bye bye tank. It can create a lot of issues for the workers and may reduce the paint tank efficiency. For clearing of a paint tank, the workers must clear all the paint out of there and rinse it away with water. This will prevent any residual paint from getting stuck inside. Again, the paint tank should also be stored in a dry and cool place when not being used to maintain its quality.

Workers can work better and faster when they get significant help from paint tanks. Having paint tanks allows workers to paint more and mix less. Which in turn results in an increased productivity rate. Furthermore, there are cost benefits in terms of reduced paint wastage as factories can also try to store paint in tanks using these paint tanks. In short, paint tanks are essential devices that ease the task for all involved.

RUMI certified ISO9001, CE other certifications CE, ISO9001 other. Additionally, we got 6 patents, High precision suspension measuring scale, Vacuum anti-corrosion mixer, paint tanks Mixer, Butterfly Mixer, multi-functional dispersing mixing equipments. It's classified ""National High-Tech Enterprise" "Specialized Professional Enterprise"

Offer pre-sales technical support training expert level. aware paint tanks needs well process requirements. Together create users how choose sealing materials mechanical shaft seals, cooling heating methods more.

paint tanks products offered RUMI include dispersing equipment (mixing machines), grinding machines (emulsifiers), reactors tanks, well high-precision batching, metering, weigh systems liquids well solids.

reasonable scientific design mixing paddle, variety combinations designs provide users variety choices mixing well shearing ( paint tanks) well homogenization (emulsification) grinding.