In the sophisticated chemical industry, the maturation of waste to earn a item is based very much on obtaining a specific fineness and distributions. It is in this crucial phase of particle size reduction and refining where industry specific milling ...

VIEW MORE

In the harsh environment of fine chemical manufacturing, such treatment of difficult to handle feed materials is a daily requirement. From high-viscosity polymers, to shear-sensitive formulations, the perfect homogeneous blend is a must for successfu...

VIEW MORE

Perfectly homogeneous mixing is often the name of the game in chemical manufacturing, especially when dealing with difficult materials. At SHANGHAI RUMI, we offer advanced mixers critical to today's efficient production. Of these, the double planetar...

VIEW MORE

Multi-section mixtures (mixtures which consist of liquids, solids and in some cases even gases such as suspensions, emulsions or pastes) are specially problematic in terms of uniform mixing, the one-of-a-kind levels are traditionally limited to mixin...

VIEW MORE

Planetary mixers form the backbone of chemical manufacturing, and are relied upon to incorporate immoderate-viscosity compounds, such as adhesives, coatings or composite. Vacuum pressure is an important fact that affects their usual performance and i...

VIEW MORE

Viscous formulations -high viscosity coats, pharmaceutical suspensions, business adhesives- need special mixing in that uniform dispersibility of particles, stable viscosity, and optimum performance as a stop-product is obtained. RUMI satisfies...

VIEW MORE

Achieving ordinary product best even during compliance with strict manufacturing schedules is a highly grave undertaking within a business like chemicals, prescriptive drugs and high-technological material- especially when operating with a formula th...

VIEW MORE

High-viscosity materials, e.g. thick drying adhesives, composite resin and heavy-obligation finishes, are an exact challenge in the business mixing: they may up to waft, cling to equipment, and must be mixed continuously to avoid the faults in a prod...

VIEW MORE

Fine chemical industries require complex mixing applications that have varieties of materials, viscosities, and processing functions. Multi-shaft mixers are the most suitable remedy since they exhibit adaptability and withstand harsh environment well...

VIEW MORE

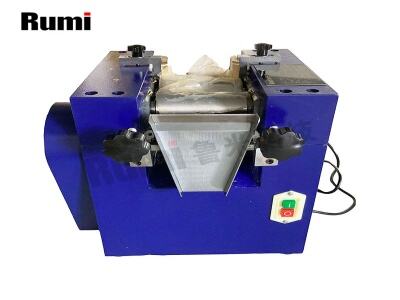

Optimal particle size distribution is imperative in many areas of manufacturing, including pharmaceutical and chemical, coatings and others. The real backbones of this refinement process have been industrial mills which have allowed the property of m...

VIEW MORE

Manufacturing industries depend on special equipment which is used to convert raw material into high quality finish products. The key role in this refining is played by industrial mills as they allow a high degree of particle size reduction and mater...

VIEW MORE

High viscosity materials also pose a challenge in mixing since the equipment handling such material must be capable of high viscosity materials and at providing good uniformity. As a solution, double planetary mixers have been developed with characte...

VIEW MORE