However, in factories that produce items such as food, pharmaceuticals, and other goods, basket machine are used to measure out just the right amount of components. These machines are referred to as “Automatic Additives Dosing Clusters. They ensure that all is tailored to perfection for the products to come out right, always.

It’s very important to add the right amount of ingredients when making products. The product might not turn out well if there is too much or too little of something. That’s where the Rumi Automatic Additives Dosing Cluster steps in. It helps make certain that all of the ingredients are included in the right quantities, meant to prepare the goods properly and speedily. This means the products are being manufactured quicker and with less errors, saving time and reducing costs.

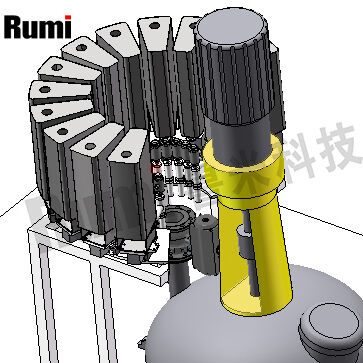

But what if a machine added ingredients into products by itself? That’s the job of the Rumi Automatic Additives Dosing Cluster. It uses technology to automatically measure and add the precise amounts of ingredients to products as they are being created. This paint bead mill makes the process of production faster and easier. More manufactured products in less time with the Automatic Additives Dosing Cluster.

When creating products, it’s essential to ensure that they come out how they are supposed to. Proper addition of ingredients helps in producing high-quality products When elements are added in exact proportions, the quality of the products is enhanced as a result of the Automatic Additives Dosing Cluster. Thus, the use of the Automatic Additives Dosing Cluster ensures more error-free, quality products to meet customers' expectations.

In manufacturing products, there is a need for consistency. Repeat customers expect the product to remain the same with every purchase. The Automatic Additives Dosing Cluster offers consistency and reliable production. Products made with the Rumi Automatic Additives Dosing Cluster are consistently the same quality because the right amounts of ingredients are added every time. This lab sand mill establishes trust with customers so they will return again and again.

variety options, including combination designs, mixing paddle scientifically designed offer variety mixing, homogenization, dispersion ( Automatic Additives Dosing Cluster), well grinding, options.

RUMI ISO9001, CE, other certifications. Additionally, we got 6 patents, High precision suspension measuring scale, Vacuum anti-corrosion mixer, Pleantary Mixer, Butterfly Mixer, multi-functional dispersing mixing equipments. classified ""National High-Tech Enterprise" "Specialized Professional Enterprise"

primary products RUMI dispersing equipment (Automatic Additives Dosing Cluster machines) grinding machines (emulsifiers), reactors tanks along high-precision metering, batching, weigh systems liquids well solids.

Provide technical assistance prior sales training expert-level. Understand Automatic Additives Dosing Cluster users requirements process design customers how select right sealing materials, mechanical shaft seals, heating cooling methods well other.