Exploring the Amazing Advantages of Three Roll Mill: Perfect for All Your Grinding Needs.

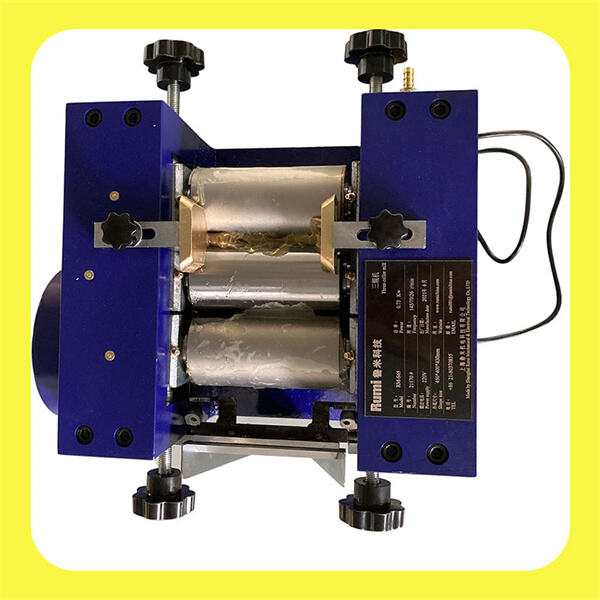

What is a Three Roll Mill and How Does It Work?

A three roll mill is a machine used in the manufacturing industry to reduce and disperse the particles of different materials, such as paint, ink, and pigments. The three roll mill has three horizontally positioned rollers, each rotating at different speeds to disperse and grind the materials. It is a simple and efficient design that enhances the quality of the final product.

The three rolls consist of two outer rollers, which rotate in the same direction, and a central roller, which rotates in the opposite direction, similar to the Rumi's product like vacuum disperser. As the material flows through the gap between the rollers, it is forced to pass through the narrow gap, producing a fine and even dispersion.

The innovation of the three roll mill has revolutionized the manufacturing process by providing a more efficient and effective way of producing high-quality products.

The three roll mill offers several advantages over traditional methods of grinding, as well as the paint agitator by Rumi. The benefits of using a three roll mill include:

1. Uniformity: The three roll mill produces an uniform product, ensuring consistency in the final product.

2. Efficiency: The three roll mill is an efficient tool that saves time and energy by reducing the number of passes needed to achieve the desired particle size.

3. Customization: The three roll mill is highly customizable, making it ideal for a wide range of applications.

4. Versatility: The three roll mill can be used to grind various materials, including high viscosity products such as grease and silicone.

Safety is paramount when operating any machine, and the three roll mill is no exception, just like the Rumi's product called paint mixer machine. Follow these safety measures to ensure a safe and efficient operation:

1. Wear protective gear, such as gloves and goggles, to protect yourself from any potential hazards.

2. Keep the workspace clean and free of obstructions to avoid accidents.

3. Keep your hands and fingers away from the rollers and moving parts to avoid any injuries.

4. Always follow the manufacturer's guidelines and operating instructions.

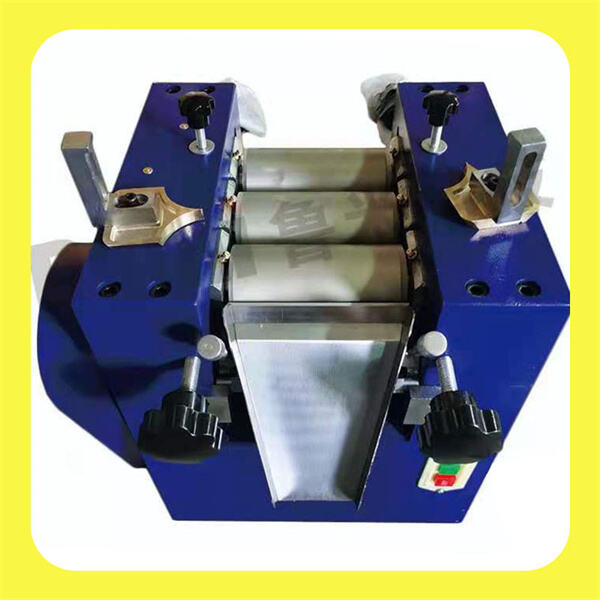

Using a three roll mill is simple and straightforward, the same as paint disperser mixer built by Rumi. Here are the steps to use a three roll mill:

1. Set the gap between the rollers according to the desired particle size.

2. Load the material to be ground onto the feed tray.

3. Start the machine and adjust the speed of the rollers according to the material being ground.

4. Collect the ground material from the discharge tray and repeat the process until the desired result is achieved.

When it comes to quality service, three roll mill manufacturers provide excellent customer service to ensure that their clients are satisfied and well-informed. They also offer training and support to ensure that their clients maximize the use of the machine.

The three roll mill is widely used in numerous industries, such as cosmetics, pharmaceuticals, and food processing, due to it is versatility and efficiency, along with Rumi's product paint putty mixer. It can be used to produce a wide range of products, including creams, ointments, and pastes.

rational scientific design mixing paddle, wide range Three roll mill designs give users wide range mixing options shearing (dispersion) homogenization (emulsification) grinding.

RUMI accredited Three roll mill, CE other certifications, including CE, ISO9001, others. Additionally, we got 6 patents, High precision suspension measuring scale, Vacuum anti-corrosion mixer, Pleantary Mixer, Butterfly Mixer, multi-functional dispersing mixing equipments. known "National High-Tech Enterprise".

Three roll mill products offered RUMI include dispersing equipment (mixing machines), grinding machines (emulsifiers), reactors tanks, well high-precision batching, metering, weigh systems liquids well solids.

Three roll mill pre-sale technical service or provide training expert level. Understanding user requirements needs, developing how select sealing materials, mechanical seals, heating cooling methods, etc.