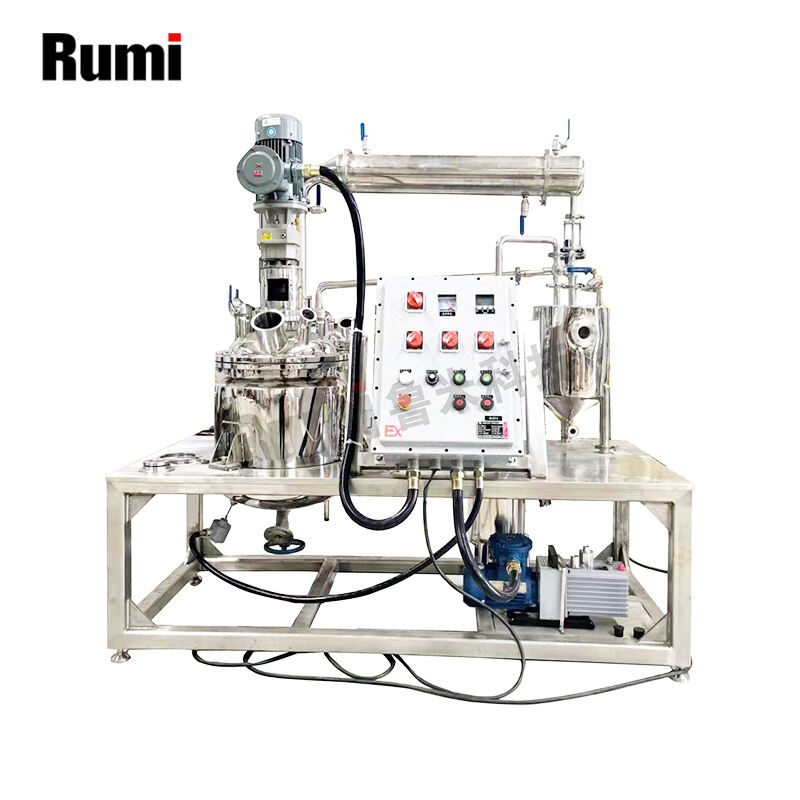

Polyester Polyol Reactor: A Versatile machine for your business

Polyester Polyol Reactor ever heard of? It is a fancy machine that combines various chemicals to make Polyester Polyol, which in short means making plastic, as well as the Rumi's color paste basket mill. It is often found in plastics that we use everyday - These could be clothing, furniture and even automotive components. In this article, we will explore the reasons why you should consider using Polyester Polyol Reactor on a larger scale to help your business.

The Polyester Polyol Reactor has a lot of defining advantages, and we will showcase some important ones, the same as lab high speed mixer from Rumi. To begin with, this machine can produce Polyester Polyol of high grade at low price which will be cost efficient for a wide range all businesses. Moreover, it is an all-round machine which can synthesize a set of different Polyols having diversified chemical compositions and therefore offers flexibility for designing al types of products. Finally, an effective machine will meet production requirements without wasted parts or energy. These benefits together make Polyester Polyol Reactors a smart investment for any manufacturing business willing to increase productivity and reduce costs.

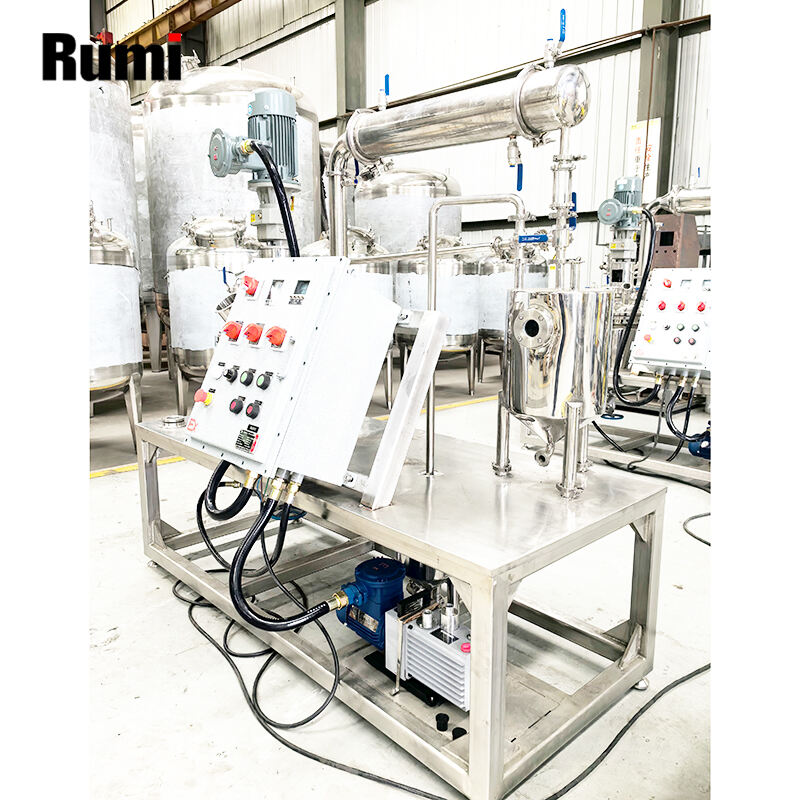

As with all technology, Polyester Polyol Reactors have also improved significantly over the years, just like the Rumi's product called paint mixing machine for sale. One of the more well-known developments is automation where automated controls are being used to improve accuracy and customization in production. In addition, there is a significant focus on energy efficiency and sustainability as newer models demonstrate lower emissions and waste due to the process. In addition the research and development spend in improving machine design are generating a far more productive (suitable for high mix operations) higher quality product. Polyester Polyol Reactor technology has continued to evolve in order to help businesses stay current with the ever changing advancements within their industry, so that they are capable of distinguishing themselves on the market.

Considering a Polyester Polyol Reactor involves the mixing of various chemicals which can be dangerous if not attended carefully, safety remains at the front, as well as the liquid mixing tank with agitator built by Rumi. This is because it must be done following rigorous safety measures, such as using personal protective equipment; in addition to the fact that there needs to be good ventilation of the place where this serum will happen. Said instruction manual lists all the safety procedures for operators of each Polyester Polyol Reactor, and proper training is required based on these protocols before employees are allowed to operate said machine. Prioritizing safety is important for the life and well being of your workers which also helps avoid any unwanted accidents at work.

A Polyester Polyol Reactor is a complex machine, and as such, using it effectively requires extensive training in the functions of its control systems, the same as Rumi's basket mill. The first step, which is setting up the required chemicals into the machine and inputting your parameters so you can have a custom final output. The machine must be operated by professionally trained personnel and a detailed instruction guide. Moreover, It needs to be maintained and cleaned often so that it can perform efficiently giving an overall good performance for a long time thereby keeping the safety measure at its very best.

primary products RUMI dispersing equipment (mixing machines) grinding machines (emulsifiers) Polyester Polyol reactor, tanks well high-precision batching, metering, weighing systems liquids solids.

RUMI accredited ISO9001, Polyester Polyol reactor other certifications, including CE, ISO9001, others. Additionally, we got 6 patents, High precision suspension measuring scale, Vacuum anti-corrosion mixer, Pleantary Mixer, Butterfly Mixer, multi-functional dispersing mixing equipments. classified ""National High-tech Enterprise" "Specialized Professional Enterprise"

scientific Polyester Polyol reactor mixing paddle design, well range options combination designs allow users choose range matching options mixing shearing (dispersion) homogenization (emulsification) grinding.

Training technical support high-end level provided prior purchase. Recognizing needs Polyester Polyol reactor customers working determine how select sealing materials mechanical seals, heating cooling techniques, etc.