This business, will provide you with advantages. This Rumi resin reactor not only speeds up how you make resin, but also the quality and reliability of what comes out.

The temperature and pressure can be adjusted directly to most important is the convenient accurate customization according to specific needs. The Rumi polyester resin reactor can also scale up and down to meet different production needs, adding operational flexibility.

Reactor is safe in any case. Proper safety measures should be followed while using reactor as just for reactivity out of control may lead to havoc. Know the Rumi epoxy resin fiberglass reactor.

Producing resin in a reactor is strictly speaking quite an easy task. This is how you use epoxy resin reactor by following the step-by-step comprehensive guide.

The unique characteristics and versatility of a reactor make it priceless tool to succeed in several businesses. Start using small resin reactor for resin manufacturing today and let the legion of opportunities open up.

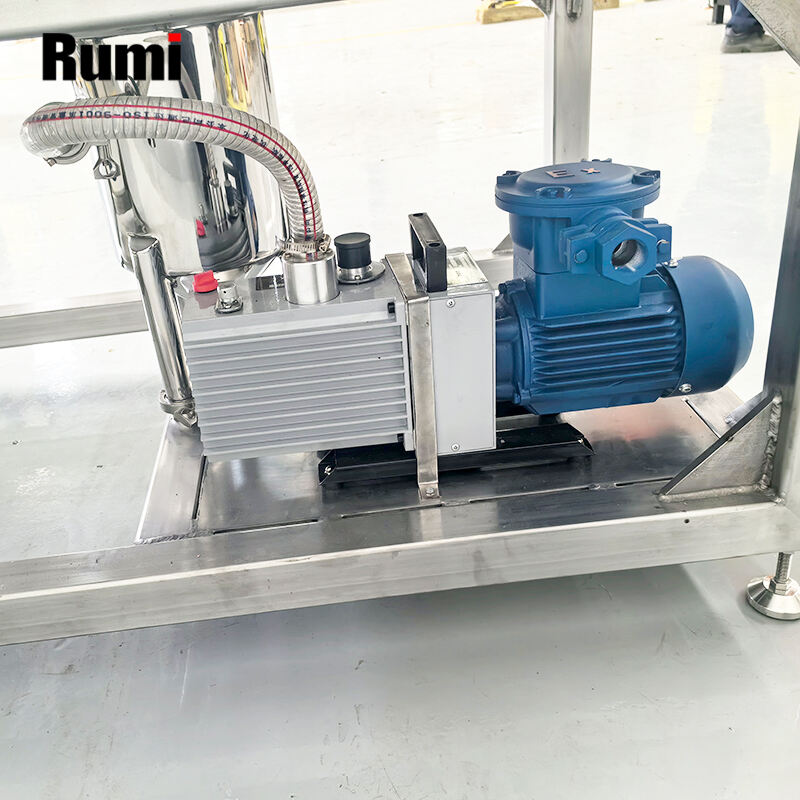

RUMI accredited ISO9001, CE other certifications like CE Reactor for resin production. Additionally, we got 6 patents, High precision suspension measuring scale, Vacuum anti-corrosion mixer, Pleantary Mixer, Butterfly Mixer, multi-functional dispersing mixing equipments. It's designated ""National High-tech Enterprise" "Specialized Professional Enterprise"

Provide technical assistance prior sales training expert-level. Understand Reactor for resin production users requirements process design customers how select right sealing materials, mechanical shaft seals, heating cooling methods well other.

variety options, including combination designs, mixing paddle scientifically designed offer variety mixing, homogenization, dispersion ( Reactor for resin production), well grinding, options.

principal products Reactor for resin production RUMI include dispersing machines (mixing machines) grinders (emulsifiers), reactors tanks along precise metering, batching weighting systems liquids solids.